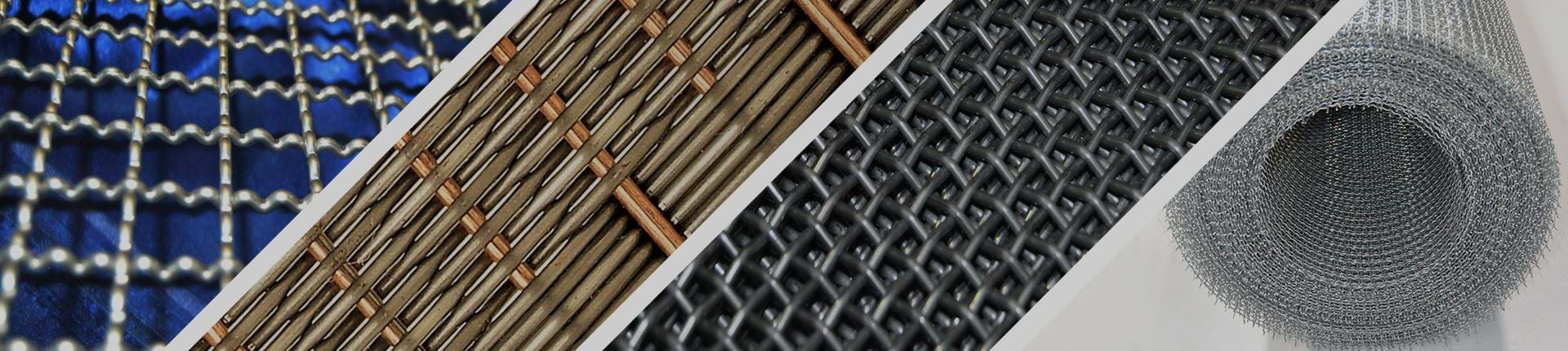

FLEX NON-STICK SIEVES

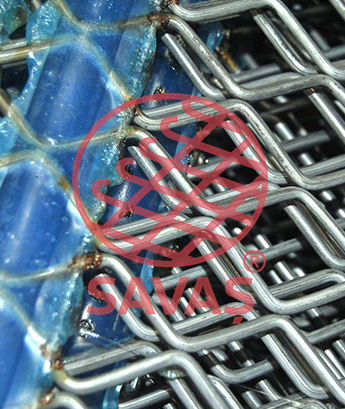

In addition to the movements of other normal sieves, the non-clogging-flex screen wires also vibrate internally in accordance with the machine vibration. In this way, the pores are less clogged and the clogging materials are removed quickly.

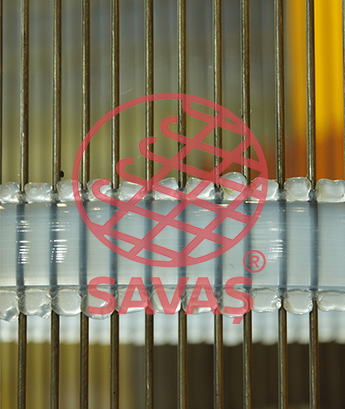

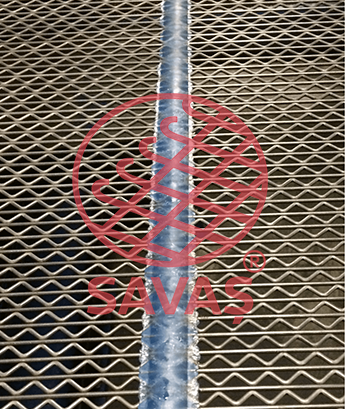

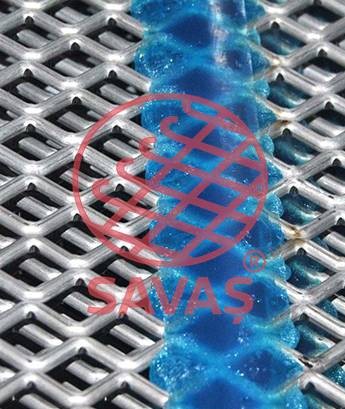

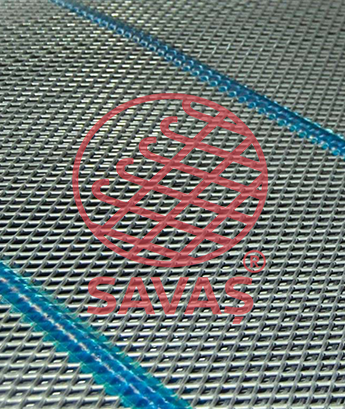

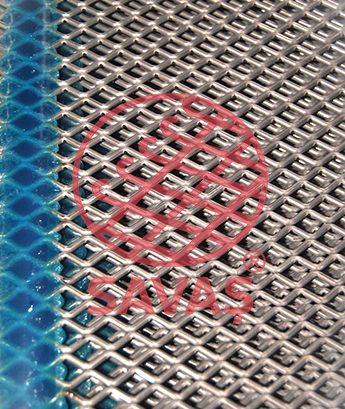

In Flex Non-Clogging Screens, each wire vibrates internally in addition to the normal screen movement. In this way, the pores of Flex Non-Clogging Screens are easily released and self-cleaning. Its efficiency in sieving problems is as high as 50%. Flex Non-Clogging Screens are used for the screening of fine-grained materials of particles that tend to stick when using square texture. Flex Non-Clogging Screens are made of wire or Polyurethane at certain intervals, all corrugated or flat. It is based on the principle of springing of individual wires and easy vibarsion of a stretched wire. It can be installed as in normal square hole sieve texture. However, care should be taken to ensure that Flex Non-Clogging Screens are located on longitudinal or transverse carriers in order to be efficient and long-lasting in transverse connections. Flex Non-Clogging Screens provide maximum screen efficiency by creating as large open screen areas as possible.

Why are Flex Screens not clogged?

Clogging, which is a problem in screening systems, has been solved with this type of screen wires. The reason is that the wires between the two support slats working independently of each other do not hold the material during vibration. Therefore, it is not washed and provides capacity increase.

Why are Flex Screens long lasting?

The fact that the wire used is horizontal, the stone does not touch the top of the normal sieves and does not abrade a point extends the life of the sieve wire. According to the silica condition of the aggregate, the life of the screen wire is between 8-18 months, depending on the stretching condition. The most important point here is that the gap between 2 slats should not be more than 250 mm, more than this reduces the life of the screen wire.